You are here

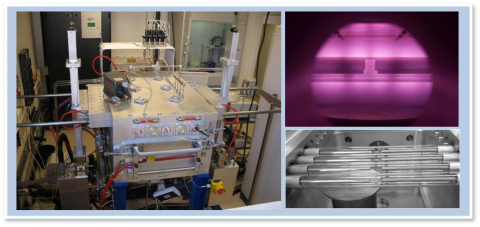

Experimental Facilities MNB

This unique system offers many advantages over classical resonance cavity based MW PECVD systems, which require high growth temperatures (>600°C) and are fundamentally restricted in deposition area due by the incoming MW frequency and cavity design. This system is not restricted by the incoming MW frequency and therefore can produce diamond (typically NCD) uniformly over large areas. In addition to the above mentioned differentiating factors, the system operates at lower pressures (<1mBar). When all the above factors are coupled together with a well-tuned chemistry, diamond growth at temperatures down to 150°C is enabled. The ability to deposit diamond at these low temperatures opens up the possible range of substrates which can be deposited on to materials such as plastics, which in a standard MW PECVD system is not possible. Also, due to the diffuse nature of the plasma 3D objects (such as coronary stents) can be coated. In its current format the system is capable of producing intrinsic diamond layers as well as boron doped layers.

This commercially available 1,5 kW CVD reactor is used for the growth of high quality intrinsic and boron-doped diamond films. The reactor is capable of producing nanocrystalline (NCD) and microcrystalline (MCD) diamond layers on a variety of substrates as well as monocrystalline diamond (SCD). The system also allows the creation of intense oxygen and hydrogen plasmas for functionalization of diamond substrates.

Other experimental equipment

- Centrifuge epenedorf miniSpin plus

- Sonicator Hielscher UP400S

- Spin coater Laurell WS-400-6NPP

- Stereomikroskop Inraco STM 1562 323O

- Digital Scales Radwag XA 52/2X

- Willamson IR pyrometer

Copyright © 2015 OFM AV ČR, v. v. i.